The refurbished refurbishment.

Replacing windows via slide-in installation is quieter, faster, simpler and cheaper.

With its innovative Nova-line window sashes Finstral offers minimally invasive window replacement that will maintain the building structure and radically reduce personnel and time costs.

Text: Anna Thaler

Photo: Erik Mosoni

A refurbishment project is underway at Alter Postweg 101. It’s not obvious at first glance, however, because there is no trace of scaffolding to be seen. No building dust swirls up. There is no noise, and no heavy machinery rolls by. All that can be seen of this large construction site in the middle of Augsburg is a barrier: a red-and-white fence that occupies just five square metres of grey ground. If you look up from here, you can see 16 floors above you: today these house a law firm, a travel agency, Augsburg technical school, university seminar rooms and numerous other workplaces. And 901 large, grey aluminium windows. Dating from 1974, the building is today a timelessly modern eyewitness to an era in which telephones still had dials.

And, like so many of the 300 million windows installed in Germany up until the 1990s, the windows of the high-rise building on the Alter Postweg no longer meet current standards. Expectations have changed too much over the decades. The demands of owners and tenants in terms of functionality, insulation and stability have increased, while builders and architects place greater emphasis on aesthetics. What has not changed, however, is the way in which windows are installed. This still uses the same technique as 50 years ago.

Maintaining the building structure

Timo Sachse, Finstral’s technical sales manager for Germany, knows of a different way to do it. He helped develop the slide-in installation method over one and a half years ago. “Why throw away valuable component parts when only part of the building is really outdated?” he thought at the time – and, together with his team, he found a way to use the frame of the existing window as a kind of mounting frame for the new window. Only the old sash and fittings are removed so that a new profile can then be inserted into the frame from the interior. The decisive element for this process is Nova-line, the Finstral sash with frame-covering glass on the exterior. The outer frame is duplicated on the inside to enable up-to-date insulation and functionality – but the external outline remains unchanged, thanks to the frameless sash, leaving the building’s appearance unchanged. Mounting work is done only from the inside so that the 46-year old façade can be preserved. Traditionally, replacing the windows would have meant completely tearing it down and rebuilding it.

The isolated location of the building – there are no other high-rise buildings nearby – also poses challenges for the refurbishment: the upper floors in particular are often exposed to strong gusts of wind and intense sunlight. “The window sashes are one and a half metres wide and almost two metres high. Tenants often had difficulty opening them at all in windy conditions, to say nothing of the space they took up. And in summer the building would overheat, so that some people would hang up sheets to protect themselves,” says Timo Sachse. The Finstral solution: in place of massive three square metre windows, easy-to-use double sashes are used instead. Nova-line, with its glass-covered dummy mullion, leaves a continuous glass surface visible from the outside while the original façade appearance is retained. The windows are easier to operate from the inside and can also be tilted.

A blind, installed between the composite sashes, now offers protection against the sun. The sound insulation value of the windows has also been improved following replacement, from 27 dB to 44 dB, while the thermal insulation is even quadrupled – from around Uw 4.0 to Uw 1.2 W/m²K. Despite the high quality of the installation, Finstral can carry out the refurbishment at a significantly lower price than that of the competition for installing simple standard windows. Of course, savings are made on scaffolding, on alternative accommodation for tenants, on masonry and painting work and on mounting time. “We were very concerned about how the window replacement would go,” says Kerstin Vogler, responsible for administering the high rise building. “And we were very relieved because it was completely free of problems. We were able to replace all the windows while people were here and the building remained fully rented out. The tenants themselves are enthusiastic: the soundproofing is much better and you can no longer hear anything when the windows are closed – even though we are right on a busy main road.”

Reduced time and personnel costs

16 floors, 901 windows, four months: there are usually five or even six fitters working in the building. They replace between 12 and 16 windows a day, five days a week and, if needs be, sometimes on Saturdays too. Mounting takes a maximum of half a day per room. The fitters are extremely flexible: if wind and weather make working on one side of the building more difficult, they just switch to the other. Windows are mounted in classrooms and offices during holidays and company shutdowns. “We are always where we are needed and where it suits the tenants,” says Timo Sachse. “This flexibility is one of the reasons why our refurbishment method saves time and prevents complications from arising.”

The principle of slide-in installation will revolutionise window replacement. Timo Sachse is convinced of this. Why? Because everyone involved benefits: the client who saves time and money – without the usual compromises in the quality of the windows. The tenants who do not have to vacate their offices and apartments. And the environment, because more of the building’s structure is preserved. The work in Augsburg for example has avoided a mountain of waste – hundreds of tons of steel and aluminium – that would have come from the façade.

Text: Anna Thaler

Photo: Erik Mosoni

A refurbishment project is underway at Alter Postweg 101. It’s not obvious at first glance, however, because there is no trace of scaffolding to be seen. No building dust swirls up. There is no noise, and no heavy machinery rolls by. All that can be seen of this large construction site in the middle of Augsburg is a barrier: a red-and-white fence that occupies just five square metres of grey ground. If you look up from here, you can see 16 floors above you: today these house a law firm, a travel agency, Augsburg technical school, university seminar rooms and numerous other workplaces. And 901 large, grey aluminium windows. Dating from 1974, the building is today a timelessly modern eyewitness to an era in which telephones still had dials.

And, like so many of the 300 million windows installed in Germany up until the 1990s, the windows of the high-rise building on the Alter Postweg no longer meet current standards. Expectations have changed too much over the decades. The demands of owners and tenants in terms of functionality, insulation and stability have increased, while builders and architects place greater emphasis on aesthetics. What has not changed, however, is the way in which windows are installed. This still uses the same technique as 50 years ago.

Maintaining the building structure

Timo Sachse, Finstral’s technical sales manager for Germany, knows of a different way to do it. He helped develop the slide-in installation method over one and a half years ago. “Why throw away valuable component parts when only part of the building is really outdated?” he thought at the time – and, together with his team, he found a way to use the frame of the existing window as a kind of mounting frame for the new window. Only the old sash and fittings are removed so that a new profile can then be inserted into the frame from the interior. The decisive element for this process is Nova-line, the Finstral sash with frame-covering glass on the exterior. The outer frame is duplicated on the inside to enable up-to-date insulation and functionality – but the external outline remains unchanged, thanks to the frameless sash, leaving the building’s appearance unchanged. Mounting work is done only from the inside so that the 46-year old façade can be preserved. Traditionally, replacing the windows would have meant completely tearing it down and rebuilding it.

The isolated location of the building – there are no other high-rise buildings nearby – also poses challenges for the refurbishment: the upper floors in particular are often exposed to strong gusts of wind and intense sunlight. “The window sashes are one and a half metres wide and almost two metres high. Tenants often had difficulty opening them at all in windy conditions, to say nothing of the space they took up. And in summer the building would overheat, so that some people would hang up sheets to protect themselves,” says Timo Sachse. The Finstral solution: in place of massive three square metre windows, easy-to-use double sashes are used instead. Nova-line, with its glass-covered dummy mullion, leaves a continuous glass surface visible from the outside while the original façade appearance is retained. The windows are easier to operate from the inside and can also be tilted.

A blind, installed between the composite sashes, now offers protection against the sun. The sound insulation value of the windows has also been improved following replacement, from 27 dB to 44 dB, while the thermal insulation is even quadrupled – from around Uw 4.0 to Uw 1.2 W/m²K. Despite the high quality of the installation, Finstral can carry out the refurbishment at a significantly lower price than that of the competition for installing simple standard windows. Of course, savings are made on scaffolding, on alternative accommodation for tenants, on masonry and painting work and on mounting time. “We were very concerned about how the window replacement would go,” says Kerstin Vogler, responsible for administering the high rise building. “And we were very relieved because it was completely free of problems. We were able to replace all the windows while people were here and the building remained fully rented out. The tenants themselves are enthusiastic: the soundproofing is much better and you can no longer hear anything when the windows are closed – even though we are right on a busy main road.”

Reduced time and personnel costs

16 floors, 901 windows, four months: there are usually five or even six fitters working in the building. They replace between 12 and 16 windows a day, five days a week and, if needs be, sometimes on Saturdays too. Mounting takes a maximum of half a day per room. The fitters are extremely flexible: if wind and weather make working on one side of the building more difficult, they just switch to the other. Windows are mounted in classrooms and offices during holidays and company shutdowns. “We are always where we are needed and where it suits the tenants,” says Timo Sachse. “This flexibility is one of the reasons why our refurbishment method saves time and prevents complications from arising.”

The principle of slide-in installation will revolutionise window replacement. Timo Sachse is convinced of this. Why? Because everyone involved benefits: the client who saves time and money – without the usual compromises in the quality of the windows. The tenants who do not have to vacate their offices and apartments. And the environment, because more of the building’s structure is preserved. The work in Augsburg for example has avoided a mountain of waste – hundreds of tons of steel and aluminium – that would have come from the façade.

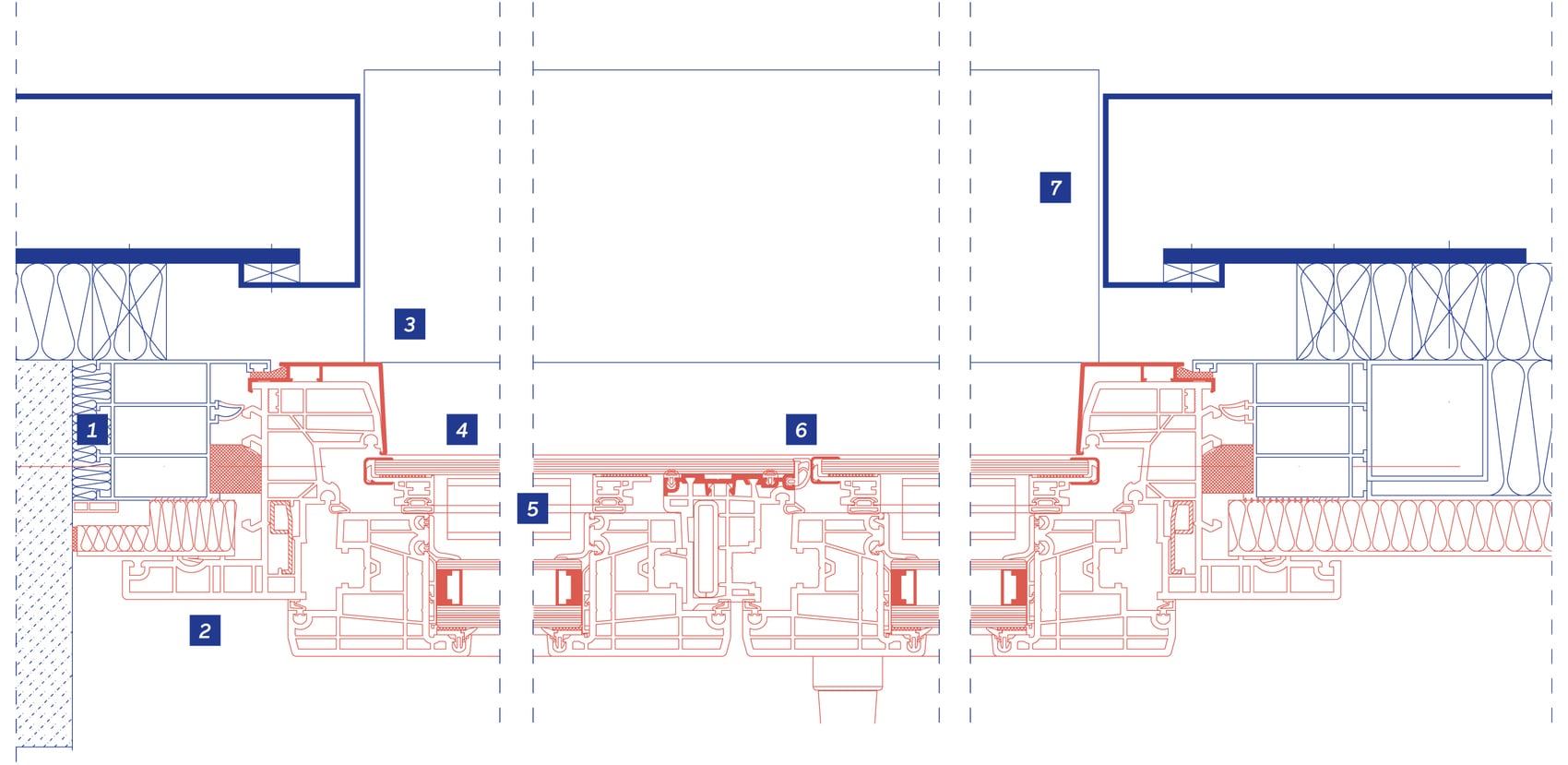

- 1 The old frame and building joint are retained.

- 2 The frame is duplicated by sliding it in from the inside.

- 3 From the outside the new frame looks like the old sash frame.

- 4 The new sash frame is designed in the frameless Nova-line look.

- 5 An internal blind is integrated into the composite sash.

- 6 The glass-covered dummy mullion makes the window easier to operate without changing the external appearance.

- 7 The façade cladding does not have to be removed as installation takes place from the inside.

The Finstral slide-in installation has been tested by the Institut für Fenstertechnik Rosenheim (ift).

One house, many windows: one of the biggest challenges when refurbishing the building on the Alter Postweg was to preserve its distinctive façade. The Nova-line window sash with its frame-covering glass and glass-covered dummy mullion meant the building’s façade was not perceptibly changed (left: before refurbishment, right: after refurbishment).

The Glöggler high-rise building in Augsburg saw 901 windows replaced in 4 months.

Still want more?

See here for further interesting reading matter.